UV barrier

Thanks to the use of additives specifically formulated according to the applications, the containers can be perfectly transparent or completely opaque to Ultraviolet...

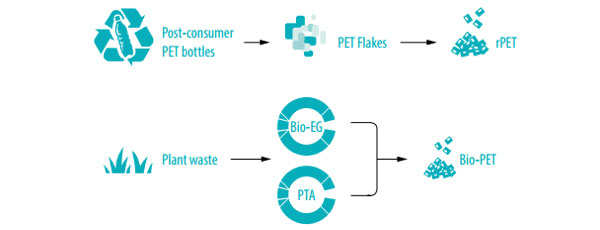

ContinueIFAP uses post consumer materials for the production of plastic packaging, especially chemical and mechanical PET for recycling. The percentages of use of post consumer PET may vary between 20% and 100% rPET. In 2017 recovered PET was used for 20% of production. Further investments are underway to increase the share of recovered plastic.

Another step by IFAP towards renewable sources and sustainability is the use of BIO–PET. BIO–PETcontains 30% of raw material within its structure deriving from renewable sources such as cane and sugar beet plant, instead of using products deriving from petroleum.

IFAP’s portfolio also includes 100% recyclable items (ECO) produced with rPET from post consumer and BIO–PET from renewable sources.

You can find all our proposals for the protection of your products within the section dedicated to the solutions on this page. Please find below links to some of the main innovations employed in the sector.

Thanks to the use of additives specifically formulated according to the applications, the containers can be perfectly transparent or completely opaque to Ultraviolet...

Continue

For carbonated drinks, in particular, maintaining the level of carbonation is obviously crucial to the quality and taste of the product. In this case the passive...

Continue

Both passive and active barrier solutions can be used in combination for carbonated drinks, for which maintaining the level of carbonation constant for long periods is...

ContinueOur laboratory or sales personnel is at your disposal

Contact us now