Laboratory

There are a series of verification and control procedures within the production chain of all production phases, from the incoming raw materials to the outgoing finished product. The various checks are carried out according to schedules defined by IFAP laboratory staff or at external, consolidated laboratories, and also accredited ones, according to requirements.

Internal controls

- Acetaldehyde content control in preforms.

- Control of T% on thick and opaque samples, by using a spectrophotometer with integrating sphere.

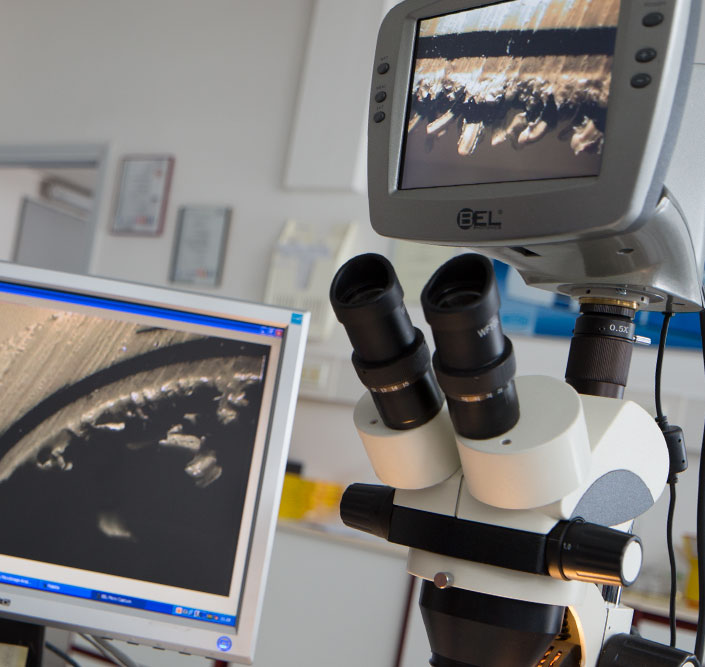

- Internal thickness control of Multilayer preform, using a microscope equipped with software for vision and measurement.

- Weight and concentricity control of the preform.

- Visual inspection of the preform and dimensional control of the thread using go/no go gauges.

- Control using Polarised Light of the preform flux lines.

External controls

- Intrinsic Viscosity Control through the ISO and ASTM method.

- Carboxylic End Groups control.

- CIE-LAB colour check.

- % Crystallinity.

- Differential scanning calorimetry (DSC) test.

- Ash control.

- Humidity Control.

- Stress-cracking test according to UNI standard.

- Overall and Specific migration test.

- Screening analysis of volatile, semi-volatile and non-volatile substances.

Our solutions

You can find all our proposals for the protection of your products within the section dedicated to the solutions on this page. Please find below links to some of the main innovations employed in the sector.

UV barrier

Thanks to the use of additives specifically formulated according to the applications, the containers can be perfectly transparent or completely opaque to Ultraviolet...

Continue

Barrier to CO2

For carbonated drinks, in particular, maintaining the level of carbonation is obviously crucial to the quality and taste of the product. In this case the passive...

Continue

Barrier to Oxygen and CO2

Both passive and active barrier solutions can be used in combination for carbonated drinks, for which maintaining the level of carbonation constant for long periods is...

ContinueWould you like to receive more information?

Our laboratory or sales personnel is at your disposal

Contact us now